2020-05-26

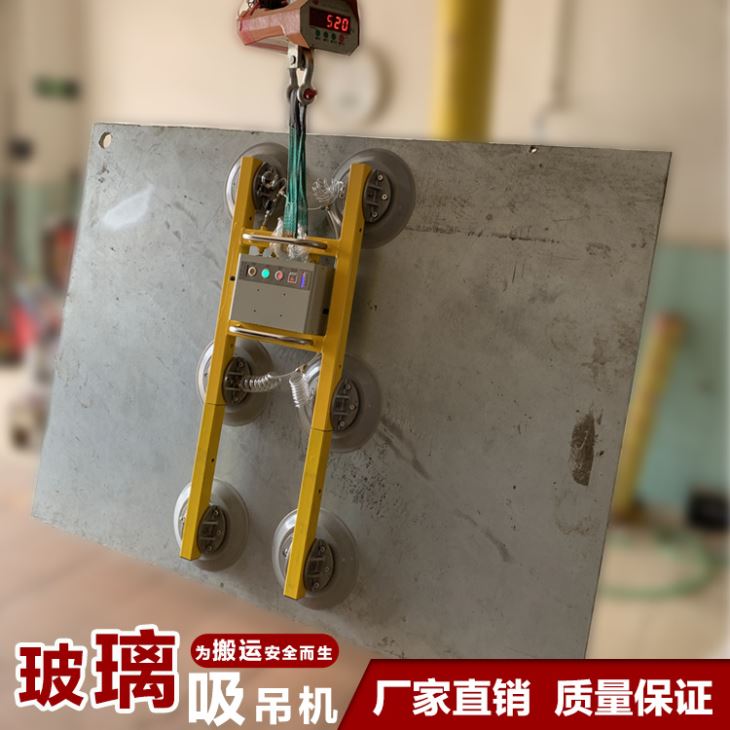

Laser machine loading and unloading users purchase vacuum manipulators for the purpose of safely and easily completing steel plate loading work. For any kind of product to be safe to use, two conditions are required: First, the product design, accessories, production, assembly, etc., so that the product itself is safe and reliable. The second is the correct use and maintenance of users to keep the product in a safe state of use.

Regarding the loading and unloading device of the laser machine, how to use and maintain it correctly? Today we will make a systematic introduction, you can refer to the following:

1. First, divide the steel plate manually, separate the upper plate from the lower one and isolate a little gap, to ensure that only one plate is grabbed at a time. Multiple sheets are stuck together, cannot be sucked, and do not meet the cutting requirements.

2. All the suction cups that need the suction plate should be close to the plate. There should be no large particles to separate the suction cup and the plate. The sling should be in a relaxed state to ensure that the lip of the suction cup fits the plate so that the steel plate can be held firmly.

3. The wires must be connected firmly to ensure that they are not broken during work and that there is no lack of phase. The cable and electric hoist chain should not be entangled, check and correct it at any time to ensure safety.

4. When the plate is sucked, when the pointer of the pressure gauge reaches the green area, the vacuum pressure is safe, and the material can be loaded.

5. The connecting rod and the fixed block, and the fixed block and the suction cup are all connected by screws. Please always pay attention to the fastening, otherwise the suction cup will fall off or the suction cup will leak air, causing a safety accident.

6. The lip surface of the suction cup is attached to the plate. Pay attention to frequently wipe and clean the lip surface, and check whether it is cracked. If there is crack, it will leak quickly and need to be replaced.

7. The filter needs to be cleaned or replaced regularly to prevent garbage from entering the vacuum pump and causing pump damage. In actual use, many filters are very dirty, and rubbish may enter the vacuum pump, jam the shaft in the pump head, and cause the pump to burn.

8. The sling is a lifting tool. Please check whether the sling is broken at any time, and check whether the fastening screws of the sling are locked to ensure safety.

9. Other fastened connection parts must be checked regularly and tightened. The main beam and the cross beam are connected, the cover plate is fastened, the electric box is fixed, the column bottom plate of the column jib crane, the end of the jib, the limit rotating shaft, the connection part of the beam and the guide rail of the gantry crane, etc.

10. The diamond palm of the telescopic main beam, pay attention to the pin limit of the telescopic beam of the main beam to prevent slipping.

11. Suction cup switch ball valve: pay attention to the opening and closing of the valve. During normal use, the valve opens. When a suction cup is not needed, close the corresponding valve.

12. Place it correctly: When you don't need to use it, use supporting feet to support it so that the suction cup does not press on the metal or the ground to protect the suction cup.

13. Vacuum pumps and electrical appliances: If the circuits, electrical appliances, and pumps fail, non-professionals, please do not try to repair them to avoid accidents and avoid damaging parts.