2020-05-26

The electric glass suction cup only needs 3-4 seconds to hold the glass at a time, and the vacuum automatic pressure holding time is no less than 30 minutes, which greatly improves the battery life. The theoretical battery can be used for no less than 1 week. The automatic pressure holding function can prevent the glass from slipping and breaking due to sudden power failure and inconvenience caused by accidental injury to workers.

Wide application of electric glass suction cups:

Steel plates, aluminum plates, copper plates, plastic plates, sandwich panels, composite panels, stone, glass, glass curtain walls, iron coils, aluminum coils, steel pipes, concrete prefabs, etc.; suitable for various types of workpieces with relatively flat and dense surfaces and regular shapes.

The working principle of the electric glass suction cup:

The electric suction cup is connected to the vacuum equipment (such as vacuum pump, etc.) through the air duct, and then contacts with the workpiece to be lifted (such as glass, steel plate, etc.), and then starts the suction of the vacuum equipment to generate negative air pressure in the suction cup, thereby sucking the workpiece to be lifted firmly Then, start to transport the workpiece to be lifted; when the workpiece to be lifted is transported to the destination, use the hand slide valve to make the electric suction cup change from negative air pressure to zero or slightly positive air pressure, and the electric suction cup will be separated from the workpiece to be lifted to complete The task of lifting and handling workpieces is improved.

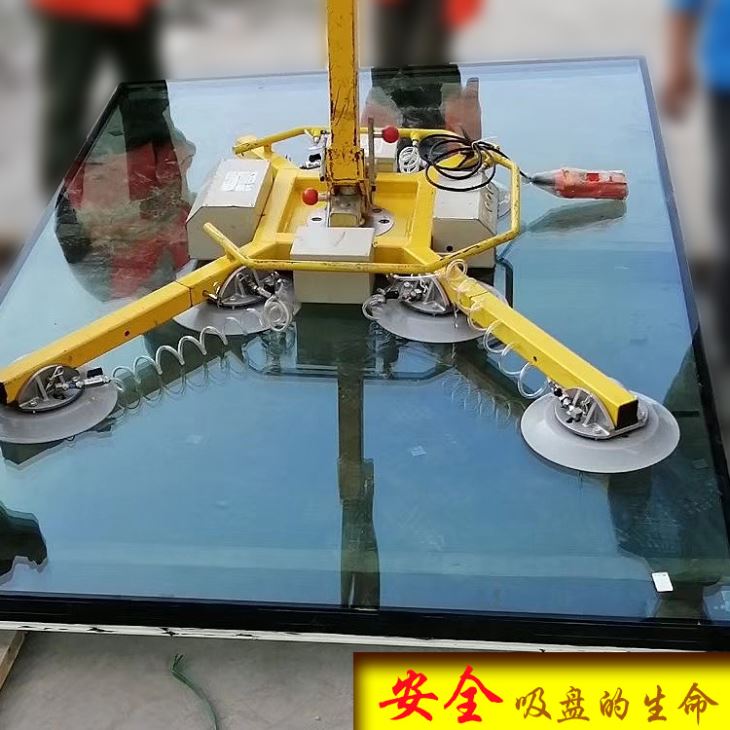

The main functions of the electric glass suction cup:

Suction cups are mainly used for glass handling equipment, used in glass production and processing, glass curtain walls, and installation of engineering glass on construction sites. The glass suction crane is suitable for handling hollow glass, tempered glass, glass curtain wall, glass deep processing, and glass transportation in solar photovoltaic glass workshops. The suction cup can be rotated by 360 degrees and can be tilted and turned by 90 degrees. The suction cup hanger is equipped with a remote control button box to ensure a high degree of operational flexibility, and is an ideal tool for flat glass handling. A variety of structures and suction cups are available for configuration, and the lifting weight can be specially designed and manufactured according to customer needs.